Dimensional accuracy repair is critical in manufacturing, auto body services, and automotive collision repair, where precise measurements are essential for product functionality and safety. Regular calibration of tools is vital to maintain quality standards, ensure process integrity, and prevent costly repairs or product failures. In auto body work, achieving dimensional accuracy guarantees high-quality repairs, customer satisfaction, and preservation of reputation. Best practices for regular calibration include meticulous record-keeping, specialized equipment, adherence to manufacturer guidelines, and controlled environments.

In the realm of precision engineering, achieving dimensional accuracy is paramount. This article explores the critical role of calibration in maintaining the reliability of dimensional accuracy repair tools. We delve into the profound impact of accurate measurements on product quality and manufacturing efficiency. Understanding how regular calibration ensures tool precision, we outline best practices for consistent maintenance, highlighting the essential steps for optimal performance in dimensional accuracy repairs.

- Understanding Dimensional Accuracy and Its Impact

- The Role of Calibration in Ensuring Precision

- Best Practices for Regular Calibration Maintenance

Understanding Dimensional Accuracy and Its Impact

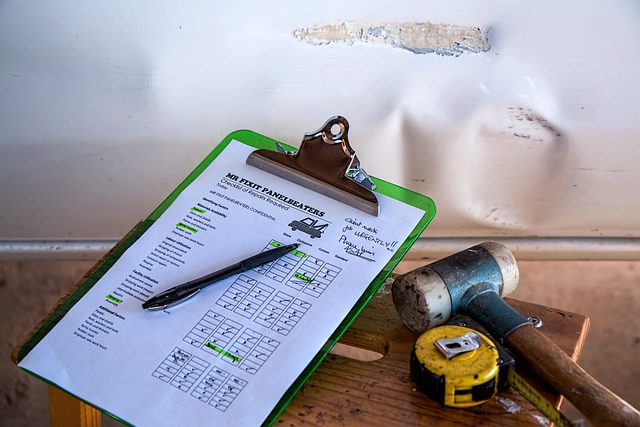

Dimensional accuracy refers to the precise measurement and comparison of physical dimensions, ensuring that objects conform to their specified sizes and shapes. In manufacturing, auto body services, and automotive collision repair industries, this is paramount as even minor deviations can significantly impact the functionality and safety of products. For instance, in a body shop service, a car’s fender must be perfectly aligned with the vehicle’s frame for optimal performance and aesthetic appeal.

Imprecise dimensions in these sectors can lead to costly mistakes, from subpar repairs to complete product failures. Therefore, dimensional accuracy repair tools play a crucial role in maintaining quality standards. Regular calibration of these tools is essential to ensure their continued precision, thereby guaranteeing the integrity of various processes within automotive body shops and related industries.

The Role of Calibration in Ensuring Precision

In the realm of dimensional accuracy repair, calibration plays a pivotal role in ensuring precision and quality. Auto body work, or car bodywork in general, relies heavily on accurate measurements to achieve meticulous repairs that match the original specifications. Tools used for this purpose must be calibrated regularly to maintain their accuracy; any deviation could lead to misaligned panels, improper fitment of parts, and overall subpar results. Calibration serves as a quality control measure, enabling auto body shops to consistently deliver high-quality services.

Regular calibration involves comparing the tool’s readings against established standards to identify and rectify any discrepancies. This process ensures that dimensional accuracy repair tools function optimally, providing consistent and reliable measurements across various tasks, from panel replacement to frame straightening. By prioritizing calibration, auto body shops can guarantee customer satisfaction and maintain their reputation for quality workmanship.

Best Practices for Regular Calibration Maintenance

Regular calibration maintenance is an integral part of ensuring optimal performance in dimensional accuracy repair tools. To maintain precision, it’s recommended to establish a consistent calibration schedule based on the frequency of tool usage and environmental factors. Calibration should be performed at regular intervals, even if the tools haven’t been used extensively, as slight drifts in measurements can occur over time due to various influences like temperature changes, wear and tear, or manufacturing variations.

Best practices involve keeping detailed records of calibration activities, including dates, results, and any adjustments made. Utilizing specialized calibration equipment and following manufacturer guidelines is crucial for accurate readings. Additionally, a controlled environment during calibration helps minimize external variables, ensuring reliable results. For car paint repair and car bodywork services that heavily rely on dimensional accuracy, maintaining these tools’ integrity through regular calibration is paramount to delivering high-quality workmanship in every car bodywork project.

Calibration plays a pivotal role in maintaining dimensional accuracy across various industries. By regularly assessing and adjusting measurement tools, organizations can ensure precision, prevent costly errors, and enhance overall product quality. Embracing best practices for calibration maintenance is not just a recommendation—it’s a strategic necessity for any enterprise committed to exceptional dimensional accuracy repair.